Introduction

Basic Concepts

Connection and monitoring are two scalable solutions. To enable monitoring you require the presence of the connection, but not vice versa.

Connection means connecting the CNC network and transfer data bi-directionally and machining programs, extending the enterprise network to the NC Machine Tool, and using special procedures to ensure the integrity and traceability of the data.

Monitoring means control the operation of the CNC and the machine dynamically retrieving information related to the productivity of the plant, to be used for statistical purposes and for the production of reports.

Connection

Valuing in an appropriate manner data input and output by the CNC

The loss of data in the company is always regarded as a serious malfunction of the system. In the case of CNC programs is very often underestimated the need and the importance of keeping up to date data archives, backup and ensuring traceability of alterations.

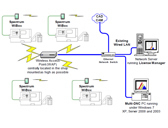

DueZero addresses these issues with the Multi-DNC software-based solution, that allows the CNC network connection. The solution allow the data transfer from and to the CNC ensuring the integrity and subsequent storage in the server data, when the information comes back as amended by the CNC machine tool, by including the automatic management of program changes history.

These simple aspects, together with operational procedures, allow you to extend the rules to the production departments of government and corporate data at the same time reducing the time to transport data to and from the Machine Tools, normally performed with makeshift equipment, including laptops , USB keys, etc..

Monitoring

Automate the production data recovery

With a simply Multi-DNC license software upgrade and using the WIBox™ devices, normally used for the program transmission to the CNC, it becomes possible to automatically collect the events generated by a series of machine states. For example, the beginning and end of the work cycle, or starting and stopping the spindle tool. These events are automatically recorded by the software in a MS-SQL database and are readily available for consultation. Multi-DNC includes a reporting system based on web technology that allows you to dynamically present, in text or graphic form, the data and statistics of production within the entire company and without any manual input. The data collected are also always available in the database to be accessed by applications developed specifically by the customer.

Analyze

What to expect from the Machine Tool Monitoring

The Machine Monitoring solution is not designed to operate production monitoring or control of personal productivity. The purpose of the application is to document in the automatic mode the most significant events that occur in the machine tool, to associate them with the number of parts or workmanship, and optionally generate alerts in case there are special circumstances, such as prolonged alarms.

This methodology approaches in a modern way the complex issue of recognition of machine time and does not purport to be comprehensive for the determination of the overall time and cost of production, but offers three advantages. First, the detection is fully automatic and can not be affected directly by external factors until these do not condition the operation of the machine tool. Second, the open structure of the data allows the convergence with other business systems, helping without overlapping the precise determination of the costs. Third, simple diagnostic tools allow you to quickly understand the actual situation of production escusivamente using web tools.

Benefit

The importance of control over business information

In addition to the benefits described above, it is important to focus on the amount and quality of data that can be brought to the attention of the company with connectivity solutions and monitoring of the machine tool. Have simple interpretations of what occurs in production departments can lead quickly to make important decisions, or may cause an approach to improvement of production, with all the benefits that entails.